VOLUMETRIC DOSING SYSTEM FOR OIL INJECTORS

CARTOTECHNICAL DOSAGE SYSTEM

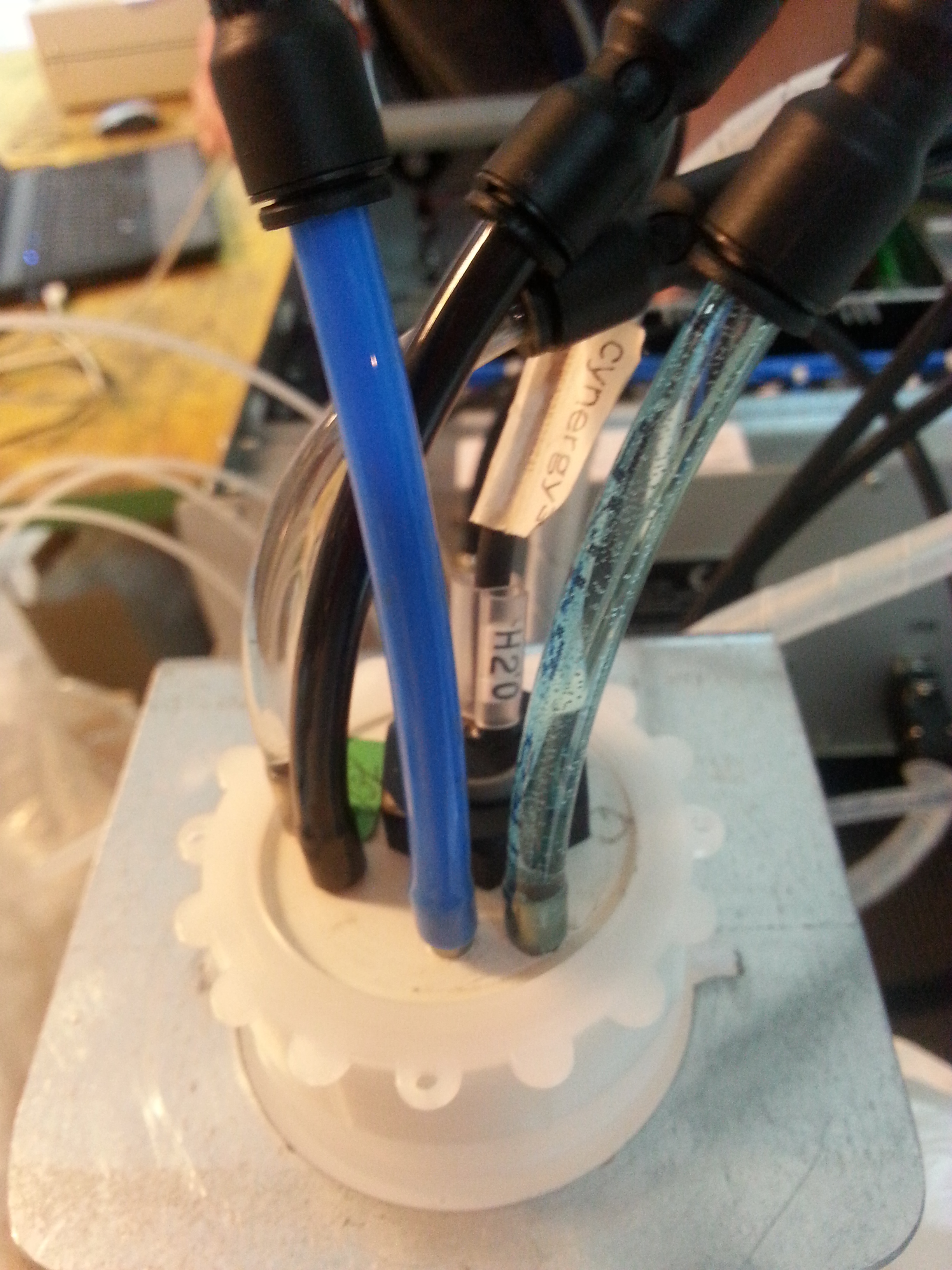

The mDSG13-200 dosing system, developed on request of a leading packaging manufacturer, is designed to integrate the cup-edge lubrication system on old-generation forming machines. The system is created in response to a problem often encountered during the forming phase in systems without dosage control, i.e.

- excessive lubrication of the cup rim, with consequent product contamination

- poor lubrication of the cup rim, with consequent formation of unsightly folds in the rim

The mDSG13-200 lubrication system can control with precision up to 5 micro-pumps with volumetric dosing system with totally separate dosing flow management.

TECHNICAL FEATURES

Power supply voltage: 230 VAC 50 Hz

Max power: 200W

Flow rate adjustment range from 0.2 ml / min to 6 ml / min for each channel

Accuracy: 10%

Repeatability: 2%

Operating temperature: + 10 ° C ÷ + 40 ° C

Overall dimensions: 430 x 410 x 150mm

Approximate weight: 20 kg

Approximate pump life> 10,000 h

Diaphragm piston travel feedback: Optional

I / O DI: START, STOP

DO: Running, Fault

I / O OF: START, STOP

DO: Running, Fault