Dosing system for food industry

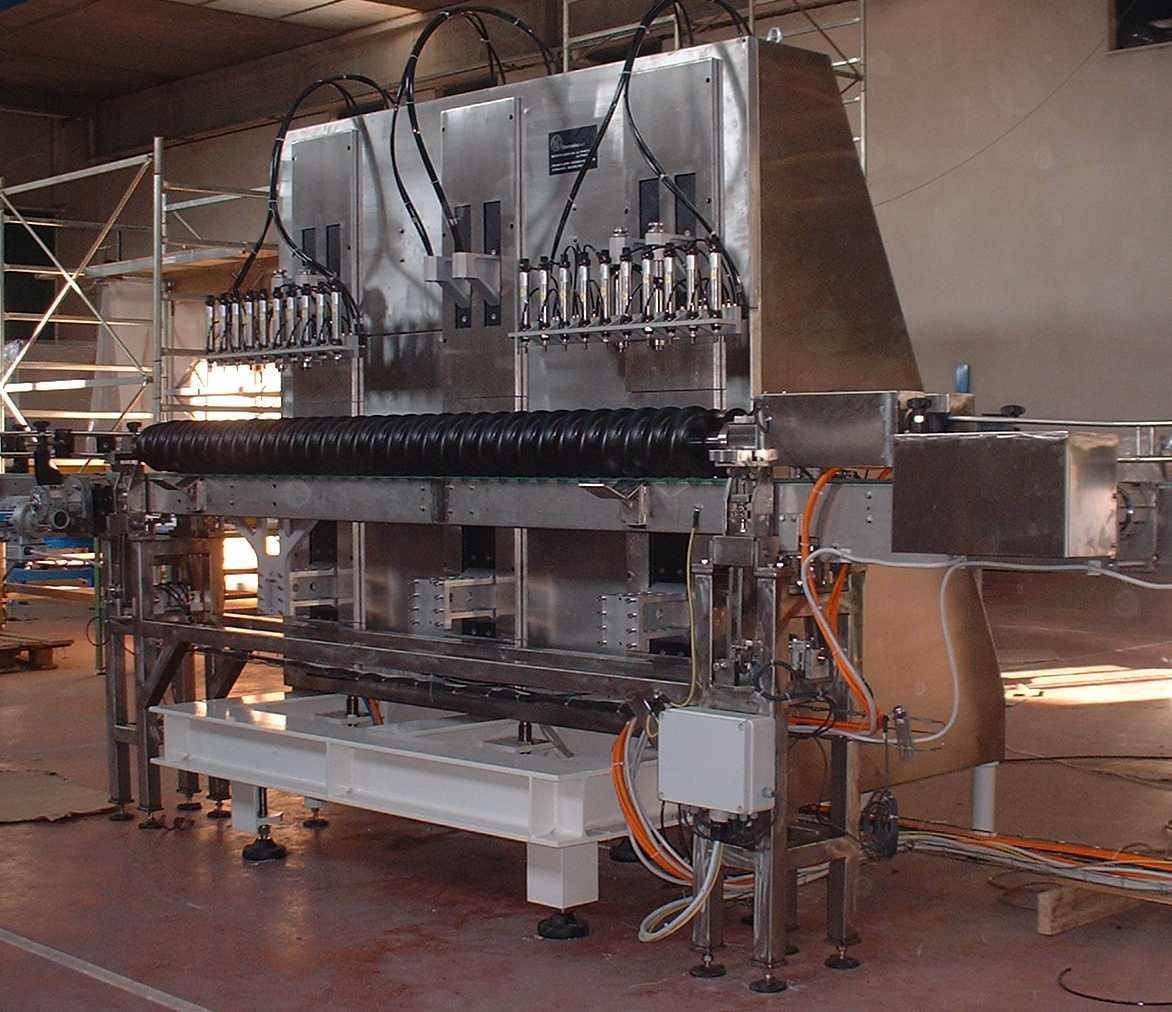

TND Elettronica dosage systems are not limited to its use in the chemical sector, but embrace solutions for the food and dairy industry. Among the special dosing applications we can include automatic gas supply and shaker systems for the production of whipped cream cans.

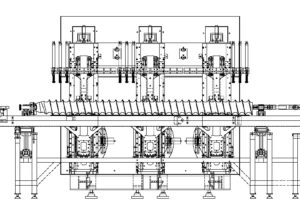

Products in compact 10-seat versions and in the 30-seat full version, the systems are able to handle different cylinder formats and can be completed with an appropriate finished product control system

TECHNICAL FEATURES

10-seat shaker

- Number of maximum cans per cycle: 10

- Maximum duration of oscillations @ 8Hz: 8 sec.

- Maximum oscillation frequency: 8 Hz;

- Oscillation amplitude: max 50 mm

- Machine productivity: 4000 pcs / h @ 250ml cans

- Spray can volume: 250 ml

- Shaker time necessary to add 7g of gas in 250ml cans: ≤ 4 sec

- Time to handle cans: ≤5 sec

- Types of processable spray cans: 2 (52mm, 57mm)

- Maximum cylinder weight: 400g

- 30-seat shaker

- Max. Number of cans per cycle: 10

- Maximum duration of oscillations @ 8Hz: 8 sec.

- Oscillation amplitude: max 50 mm

- Maximum oscillation frequency: 8 Hz;

- Machine productivity: 9000 pcs now

- Can formats: 100ml – 150ml – 250 ml – 315ml – 400 ml – 500 ml

- Can diameter: 53 ÷ 66 mm

CAN CHECKING SYSTEM

Installed downstream of the shaker, the test system automatically checks the amount of pressure contained in spray cans by applying light pressure to the spray can and verifying that the reaction force is within the set limits. The pieces found to be non-conforming to the test are expelled from a waste unit (pusher), while the compliant products are conveyed to packaging devices.

Machine capacity

Maximum line productivity 12,000.00 pcs / h

Maximum line speed 30mt / min

50mm minimum can diameter

Maximum can diameter 100mm