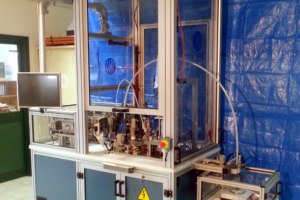

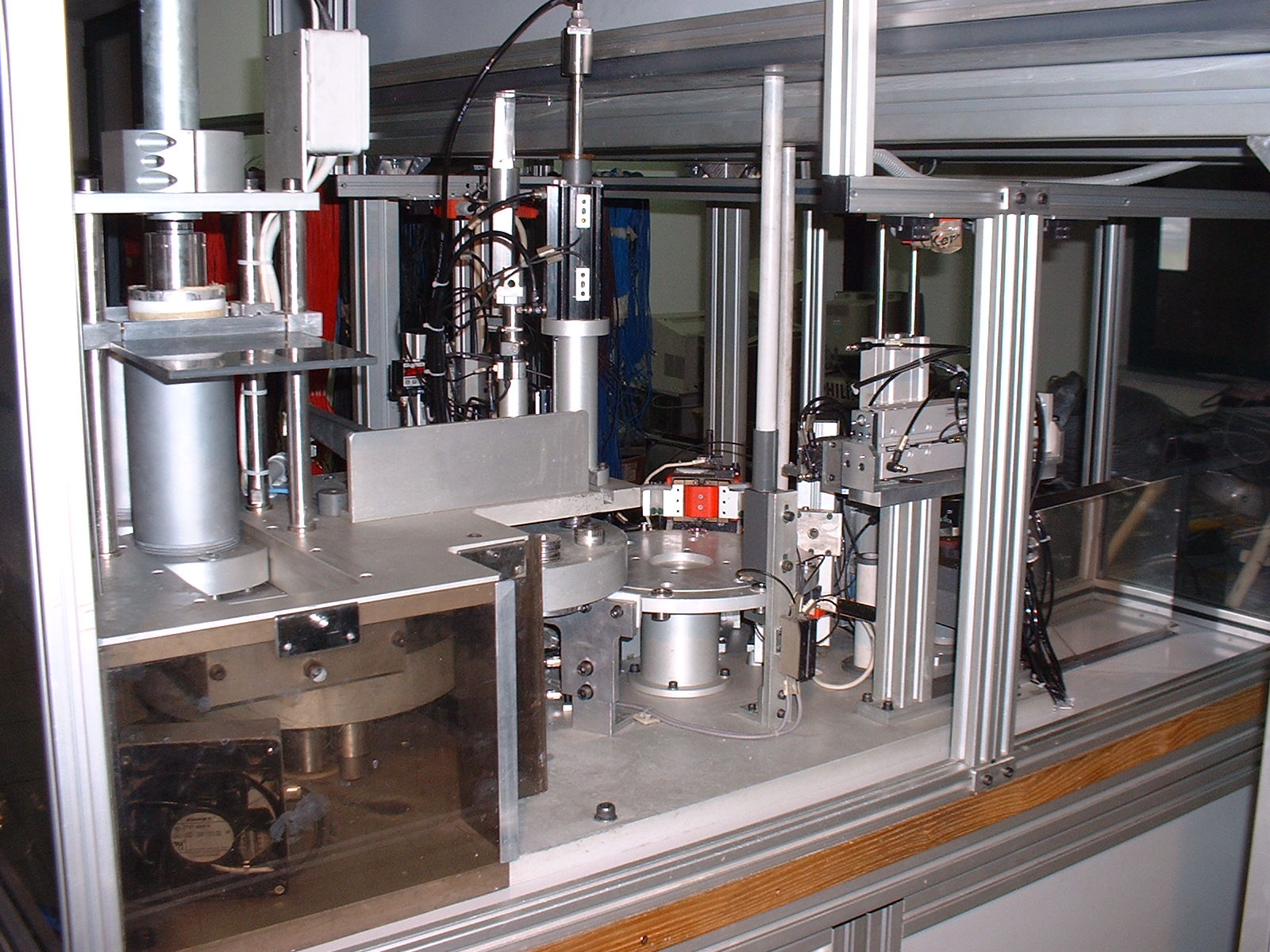

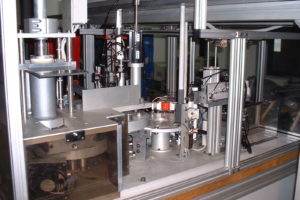

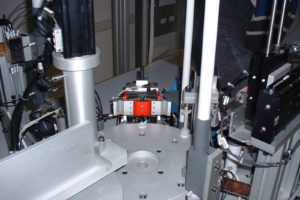

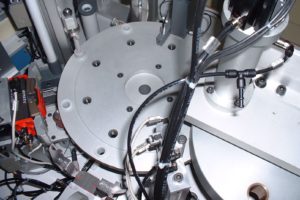

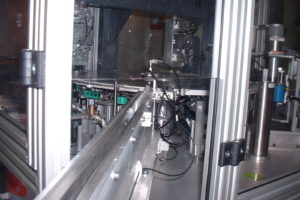

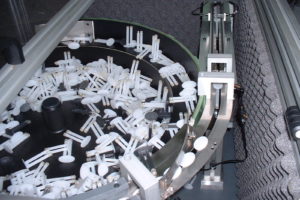

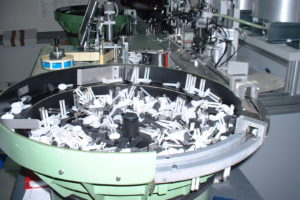

MANUAL SYSTEM FOR DOSING DENTAL PASTE IN SINGLE-DOSE CARTRIDGES AND SYRINGES

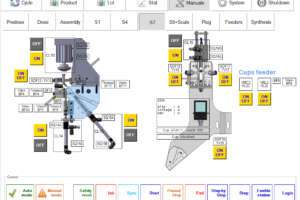

It allows the transfer of composite material from a cartridge, possibly heated, to syringes or single-dose containers in controlled and precise doses. The system allows the minimum dose of 0.20 gr. The operator positions the syringe or the single-dose tip in the machine, activates the dosage control and then has the time to manually apply the piston and the cap in both cases. The system is equipped with suitable control software for the management of multiple filling stations and allows printing a production report. Average productivity is about 250 syringes or single doses per hour.