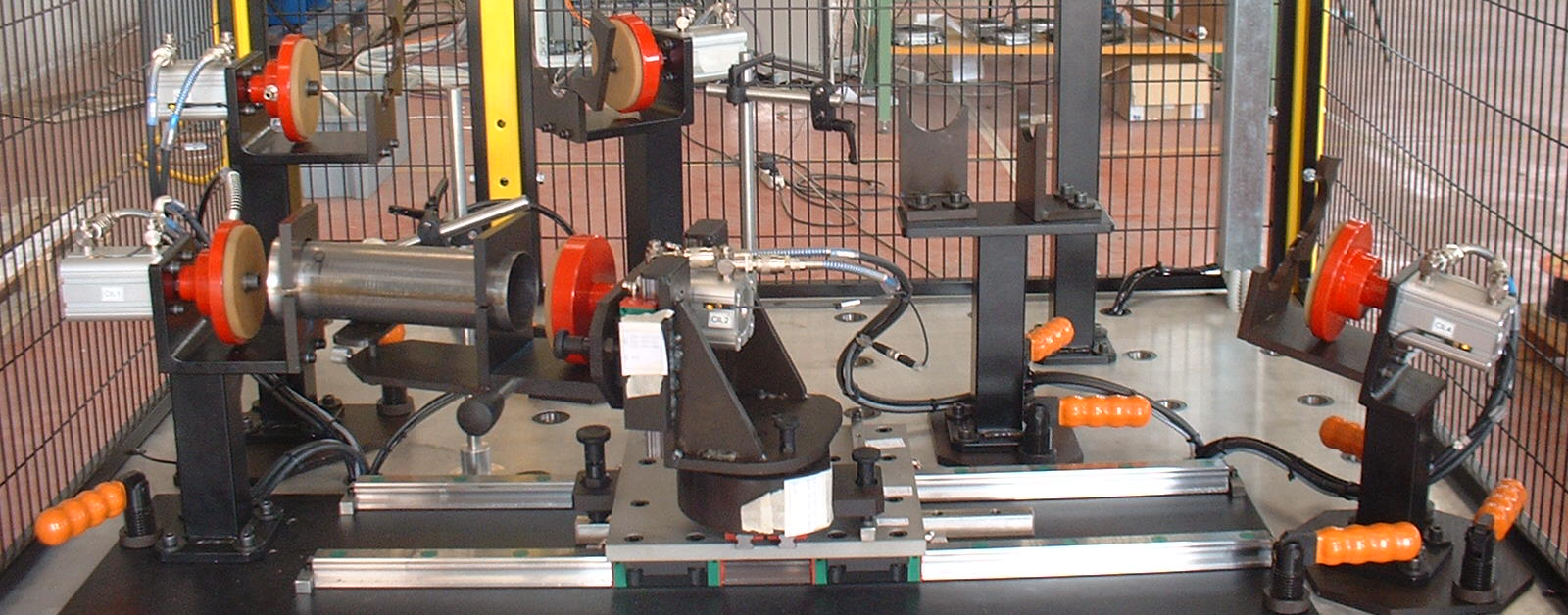

The SPM15 instruments are designed for the testing of silencers and catalytic converters in terms of tightness.

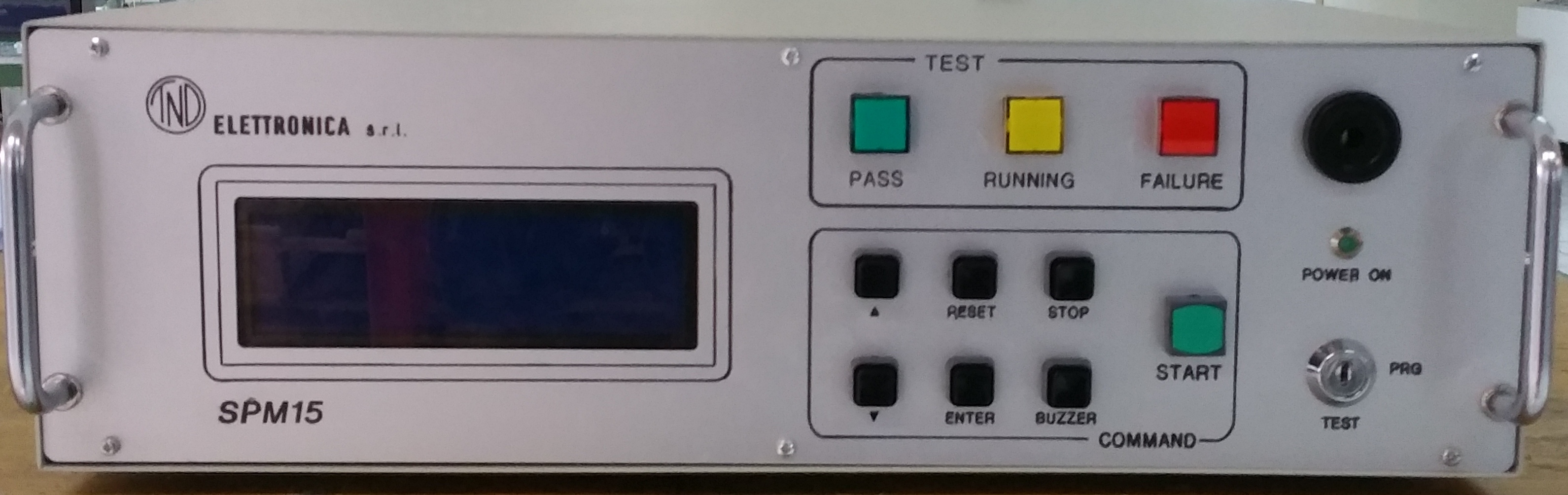

The control CPU, in addition to guaranteeing excellent results in terms of measurement accuracy, allows simple and immediate user interface management.

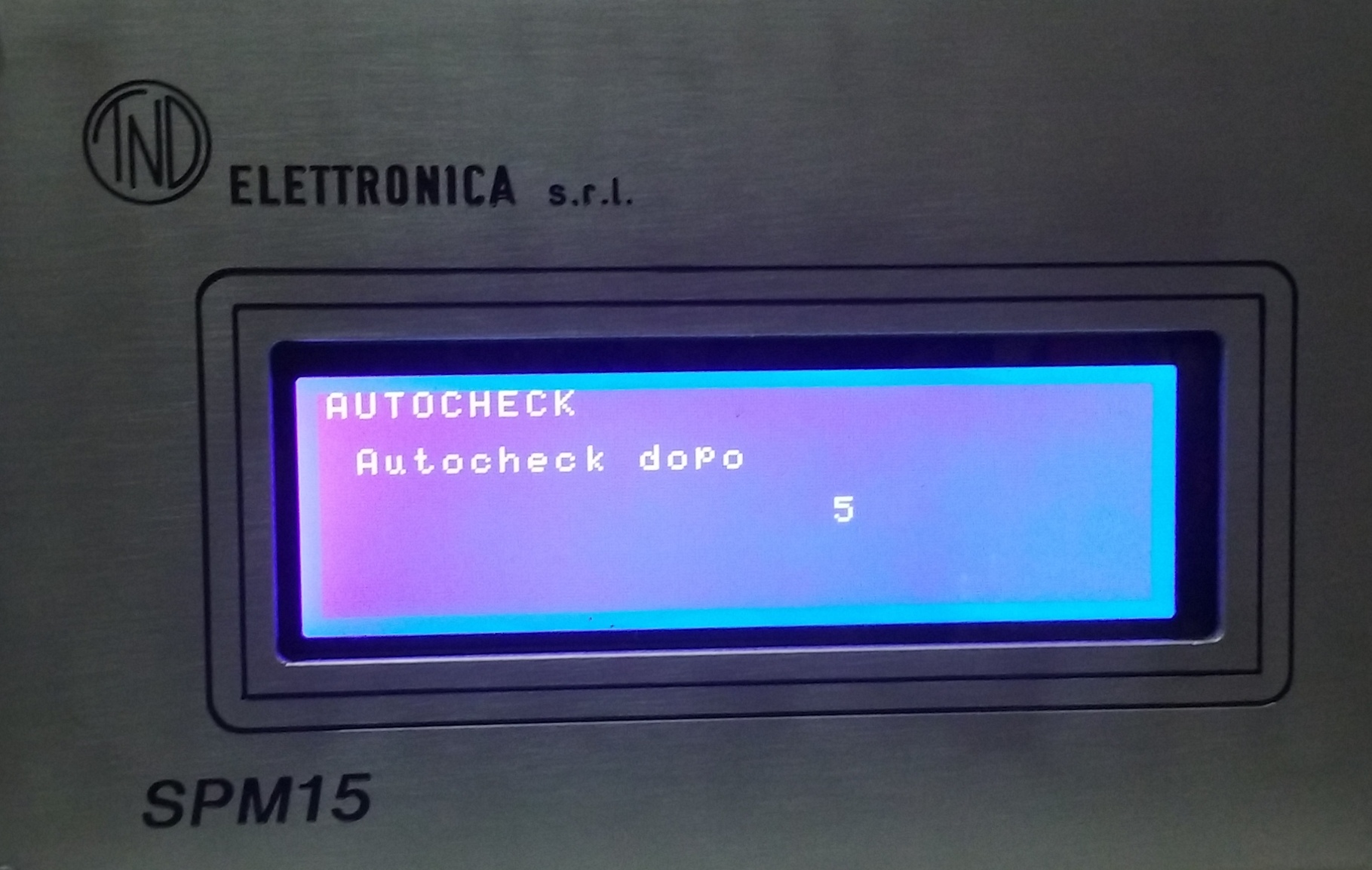

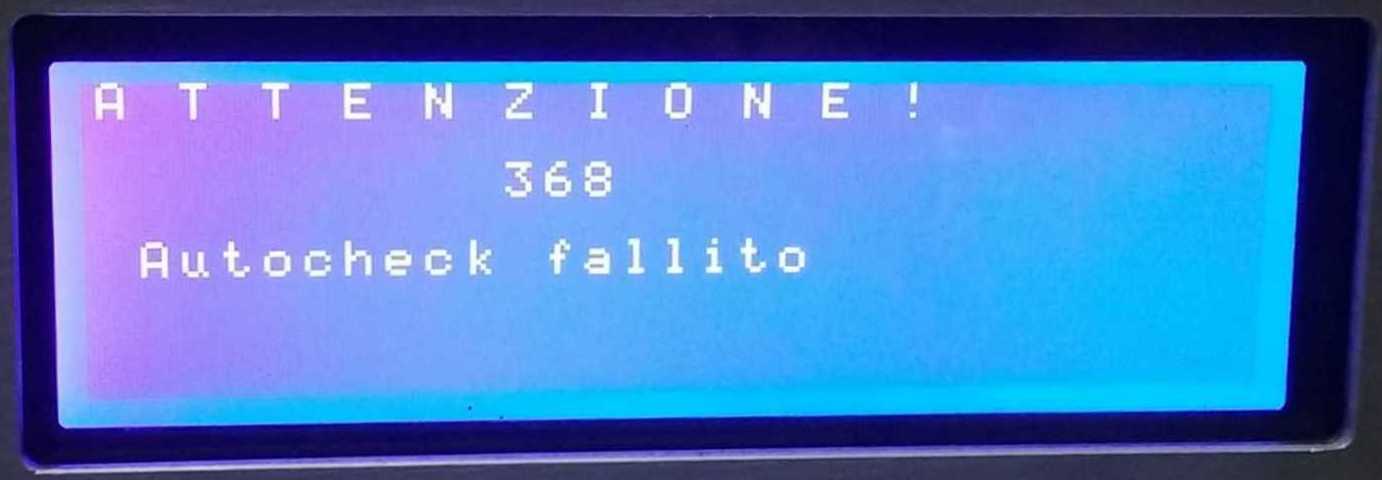

The graphic display shows the current test configuration data and the final result.

All instruments are equipped with a precise programmable pressure generator designed to always guarantee optimal test pressure regulation.

The instruments can be controlled and configured locally through the front push-button panel or remotely using decoupled digital I / O or an RS485 data connection (or both).

The tool is designed with the aim of improving the objectivity and traceability of production tests, minimizing the operator’s intervention and maneuvers and minimizing the possibility of errors and malfunctions.

On the rear side of the instrument there are are the air connections, a pressure regulator and interface connections to the instrument.

By connecting to the RS485 data port, it is also possible in addition to configuring the test parameters, also to display, store and recall the curves of each individual test through the sw SPM07_Studio, also allowing to control the device remotely for possible assistance.